Role : Concept and development in collaboration with Daniela Sanchez Marino

Company : Final Thesis for College

Cool facts...

Bamboo stands out as one of the world's most sustainable resources, with Colombia boasting over 100 species out of the more than 1,000 known globally, including the notable Guadua (Angustifolia kunth). As one of the fastest-growing plants on Earth, bamboo can be harvested annually, regenerating naturally from its roots without the need for replanting or crop rotation. This remarkable grass can grow up to a meter per day, reaching maturity in just 3 to 6 years, depending on the species. Bamboo's impressive tensile strength makes it an excellent construction material, while its versatility extends to furniture, flooring, textiles, and numerous other applications. Its rapid growth cycle, coupled with its wide range of uses, positions bamboo as a highly sustainable and eco-friendly alternative to traditional materials, particularly in regions like Colombia where it thrives.

So, how do you take advantage of the plant (guadua) to make sustainable products, but at the same time deliver an ecological message? after long nights of brainstorming, coffee and pizza, we realized one of the best solutions to learn and teach is by playing. So, we decided to create something for young kids to be taught and interact with nature by playing. We selected the range between 3 – 5 years old because at this point most children have covered the areas of mobility, gaming, speech, conduct and they are starting to learn and wonder more about their surroundings. The idea is to aim against sedentarism and loneliness that a digital world creates and bring back the basics of interacting and learning directly from nature taking advantage of 3 basic concepts :

Exploration, Observation and Recollection

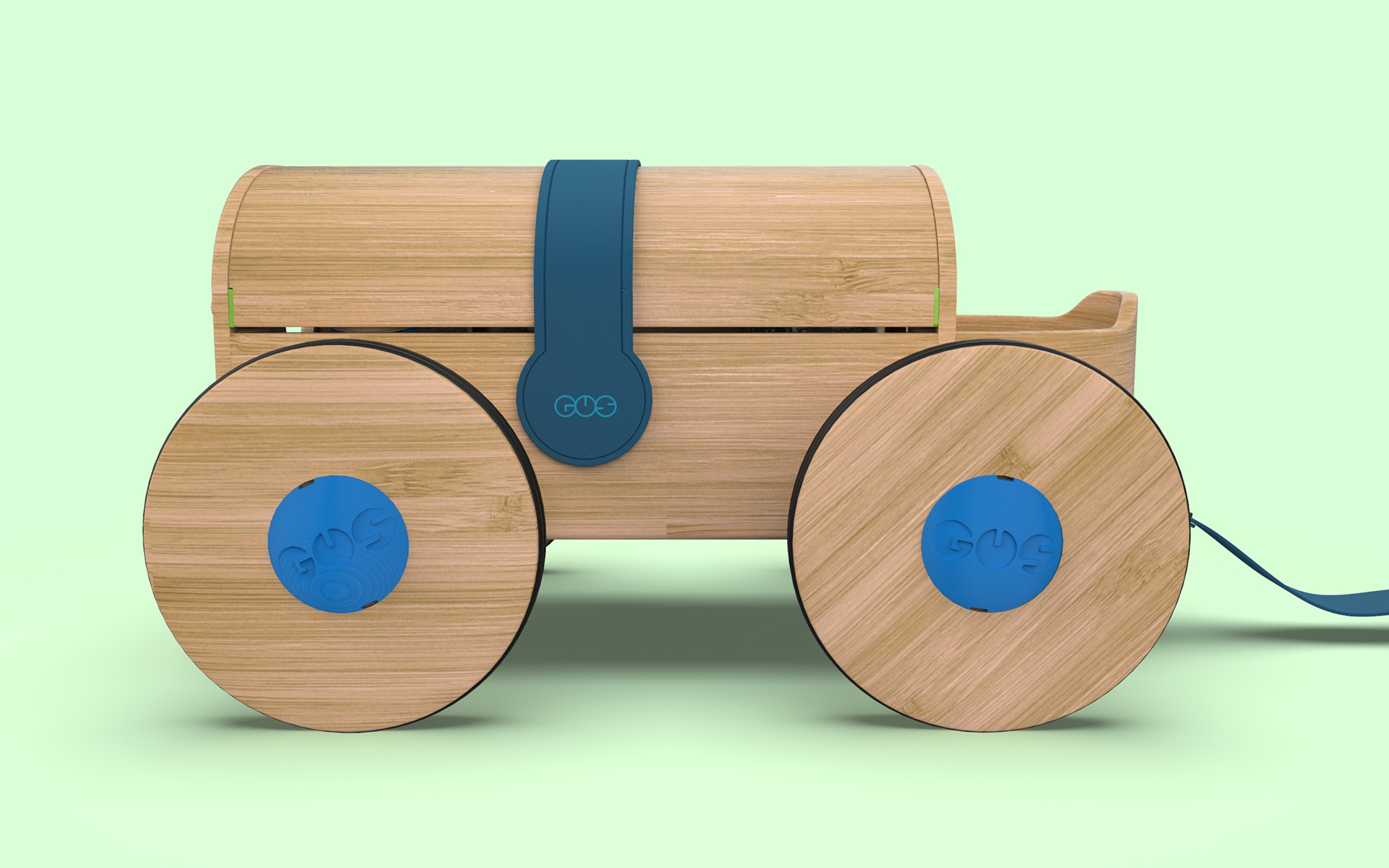

GUS is an interactive approach to truly “interact” with nature, elements such a shovel, small rake, a magnifying glass with multiple colored filters and a coloring note book to register findings among other elements, allowing the kid to create a real bond with nature. It was designed to take advantage of flexible manufacturing processes such as CNC cut and 3D machining. All the plastic parts are 3D printed in PLA, a biodegradable plastic derived from renewable resources such as corn or sugar cane. These combination of manufacturing processes allow individual customization in colors and some details of the product.

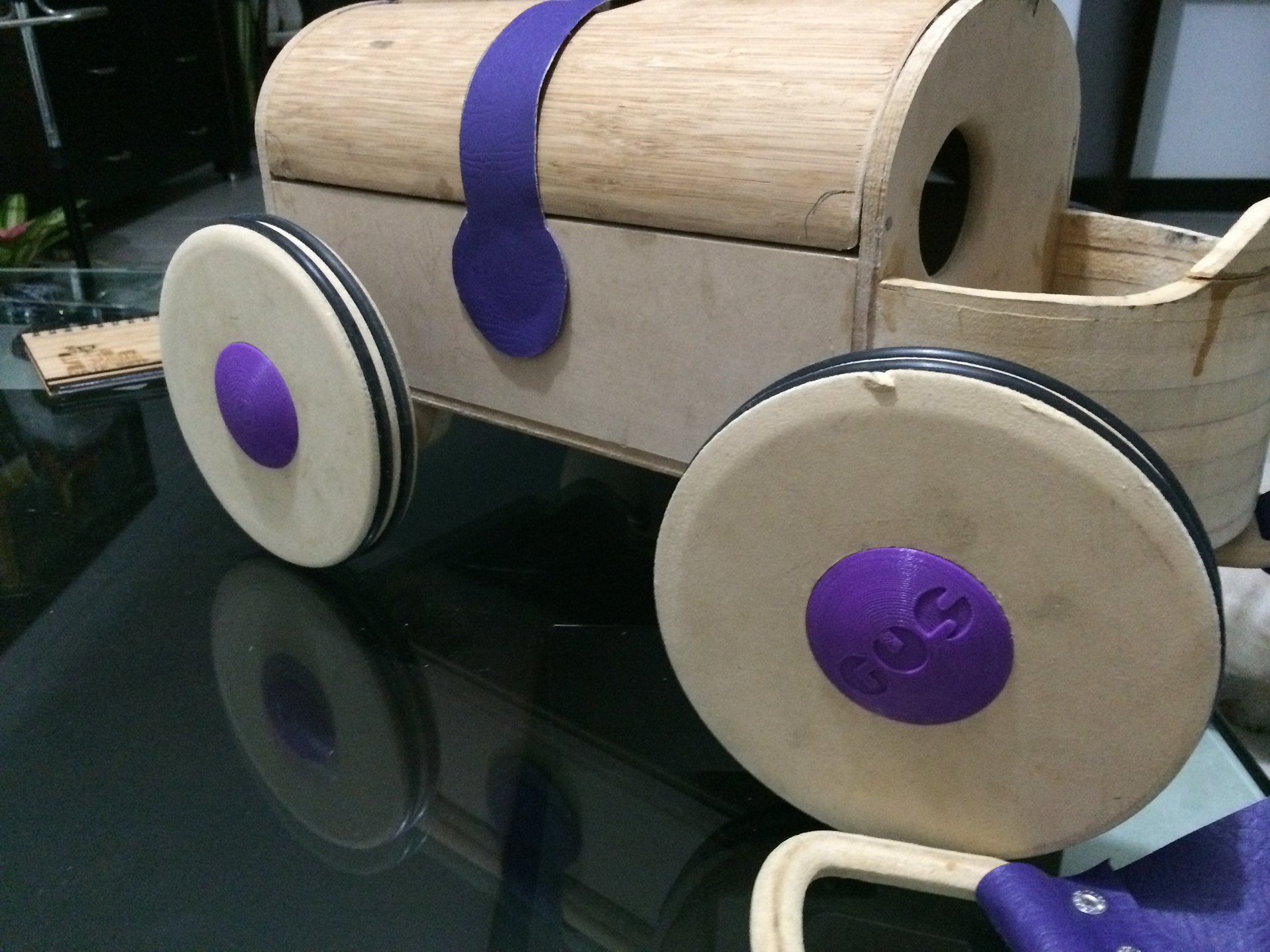

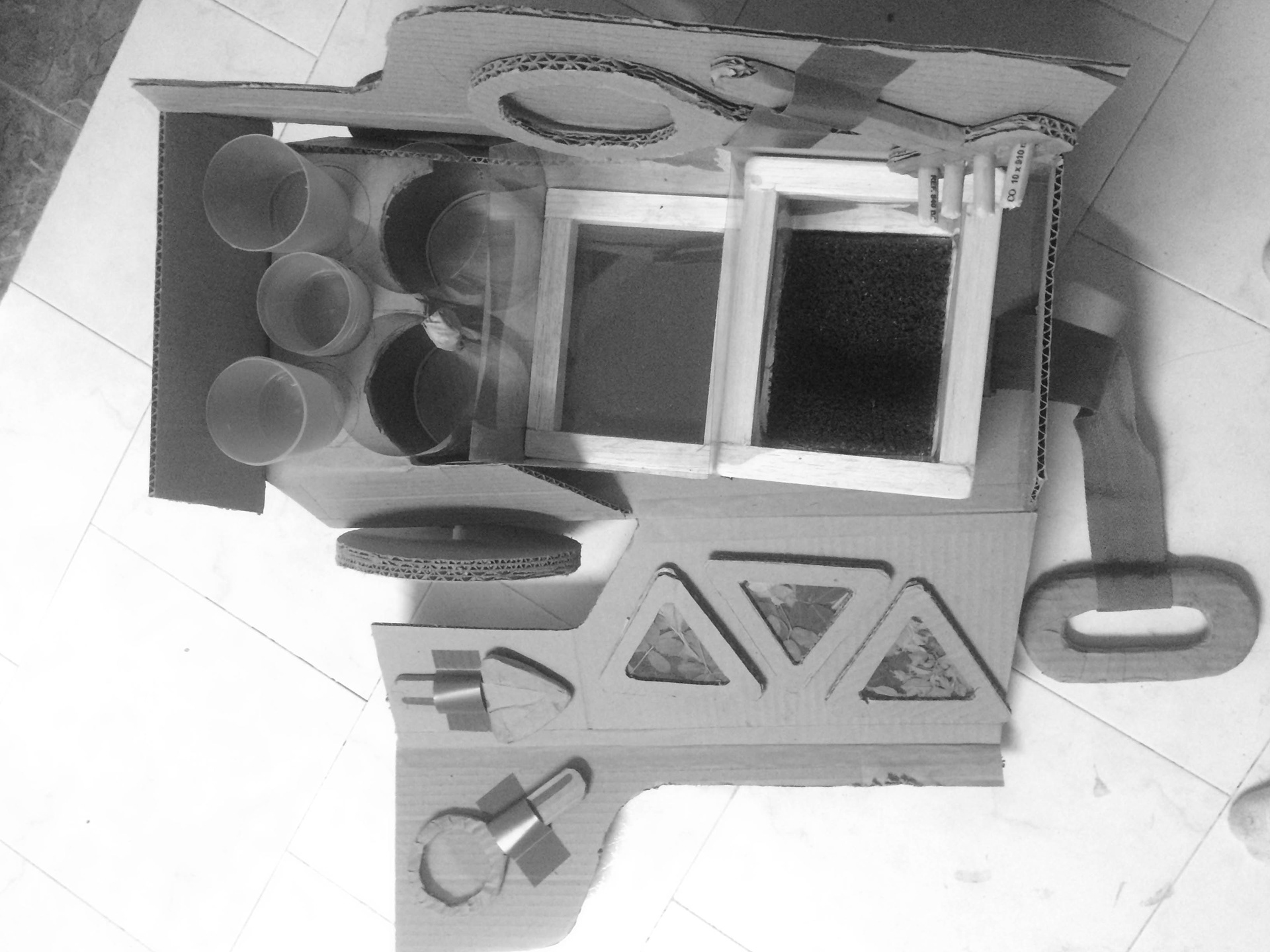

Proof of concept

We tested our assumptions about what items to create by making mock ups and giving them to an army of kids. We ended up being taught by them, learning what worked, what didn't and what needed to be included.

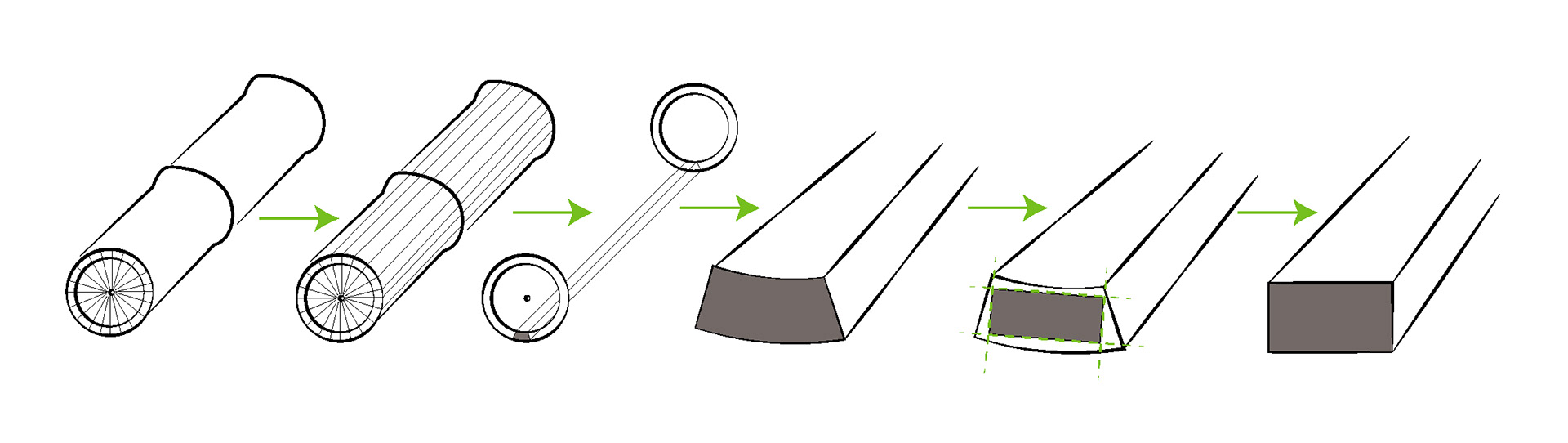

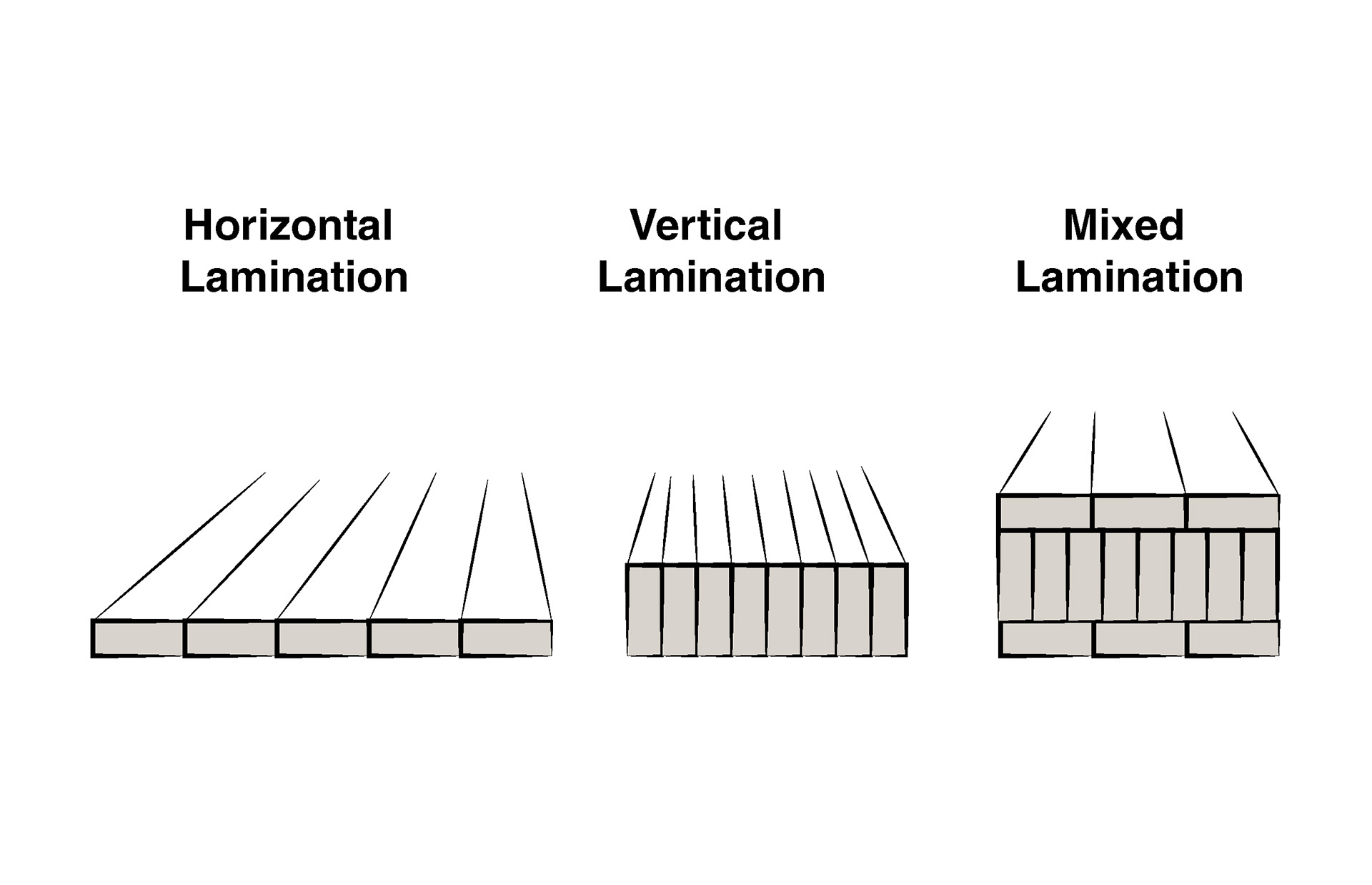

Learning about the material. Going from Bamboo tree (Guadua) to planks

We partnered with a local plywood manufacturer to understand the manufacturing process of going from a Bamboo tree to an usable flat plank of material. We wanted to keep the manufacturing processes as flexible as possible so it was crucial to learn the advantages or disadvantages of the material.

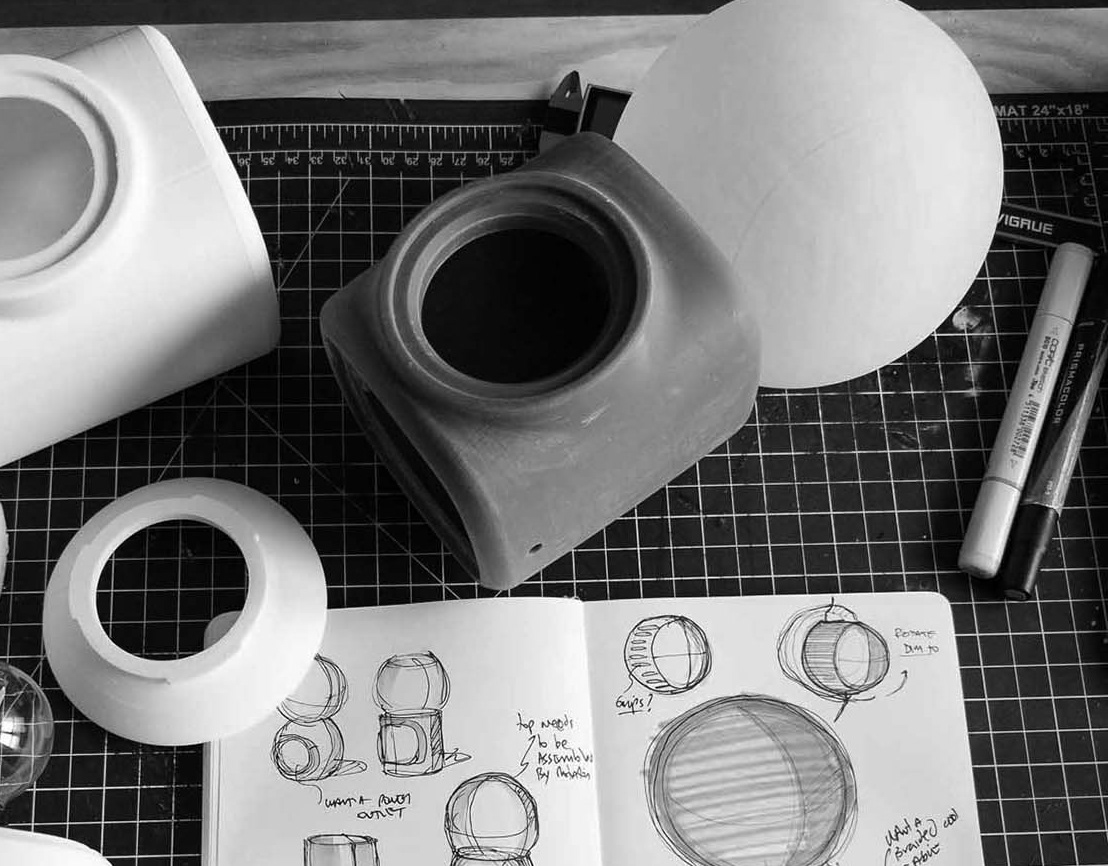

Iterate, Test, Break, Repeat...

Through out the whole process we tested and mocked up our ideas in multiple materials, tested shapes, and sizes to ensure each part was perfect for kids hands and bodies. We wanted to make sure the whole product was carefully thought. From the fitting of the 3D printed parts to the radii for the CNC. We are really proud of the final product :)